TECHNOLOGIES

For more than 80 years, we have been providing the industry with the construction and installation of sheet stretch forming, profile stretch forming, elastoforming, hot forming, superplastic forming machines as well as linear friction welding machines.

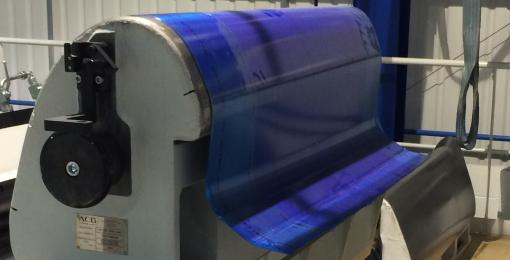

Sheet Stretch Forming

Stretch forming is widespread in the aerospace industry. It allows the manufacture of large parts, most often made of aluminum, with lower tooling costs than those of the drawing tools, as only a single run is required to form the part, on a single die.

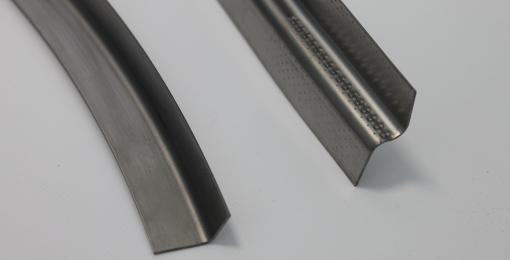

Profile stretch Forming

Profile stretch forming is a very repeatable process for profile forming in 2D or 3D with the following advantages:

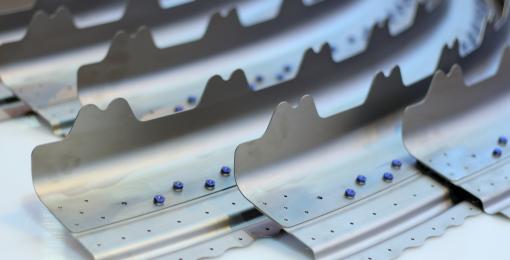

Elastoforming

Elastoforming is an economical and high productivity forming technique to stamp shallow parts. The process uses high pressure to press a blank into a die using flexible, high strength elastomer pads.

Hot Forming

Hot Forming is a punch/die forming technique with a short cycle time using medium-high temperature to increase the formability of the material being formed.

Superplastic Forming

Superplastic Forming Process

The superplastic forming (SPF) process has emerged as a reliable method of manufacturing in the aerospace industry. This technology is used for the production of complex aircraft parts.

Linear Friction Welding

Linear Friction Welding is a solid state welding at forging temperature. The heat is generated by the friction.

The process is generally divided in 4 phases:

Customer Support

ACB offers

Training

ACB offers basic or continuous training programs.

The aim is to provide the user the necessary tools and knowledge for an optimized machinery use.

Discover this service