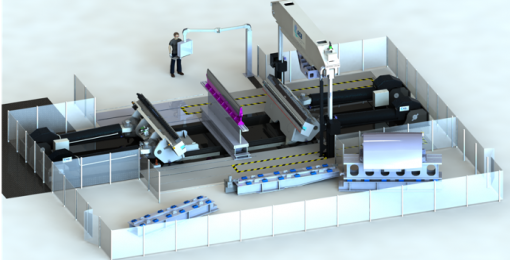

Die Management Solution (DMS) for metal forming presses

Our Philosophy : Work in Hidden time, Safely and Automatically

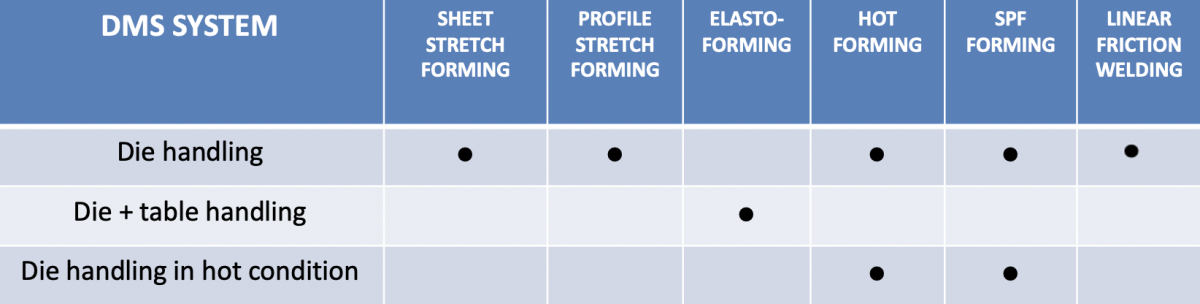

Overview of different DMS systems available:

DMS on VTL, L & T presses

- Two I/O Stations, die preparation in hidden time

- Compatible with automated clamping on gantry

- Change over time < 9 minutes

DMS on Transversal Sheet Stretch Forming Press

- Two I/O Stations

- Change over time < 7 minutes

- Compatible with automated clamping on gantry

DMS on Profile Stretch Forming Presses

- Two solutions : Rotary loader or AGV

- No human presence during die transfer

- Up to 40% extra production capacity

DMS for Elastoforming Presses

- Two solutions : Several tables managed by a lift system or by a carousel

- All transfers are done within a safe enclosure

- Several operators can use the press at the same time

DMS for Hot forming and SPF Presses

- Two solutions : Handling at floor level (HDL-F) or through a gantry system (HDL-G)

- Capability to load in hot condition the press and/or the pre-heating furnace and/or cooling cocoon

- 100 % operator protection during heating / transfert / cooling

DMS for Linear Friction Welding machine

- Fully automated cells

- All the operations of tooling transfer and installation into the machine are automated

- Very high accuracy and repeatability in the production process.

Customer support

ACB Offers

Manufacturing Engineering

A turnkey solution to perform stretching, superplastic forming or hot forming industrialization, from part definition to production.

Discover this service