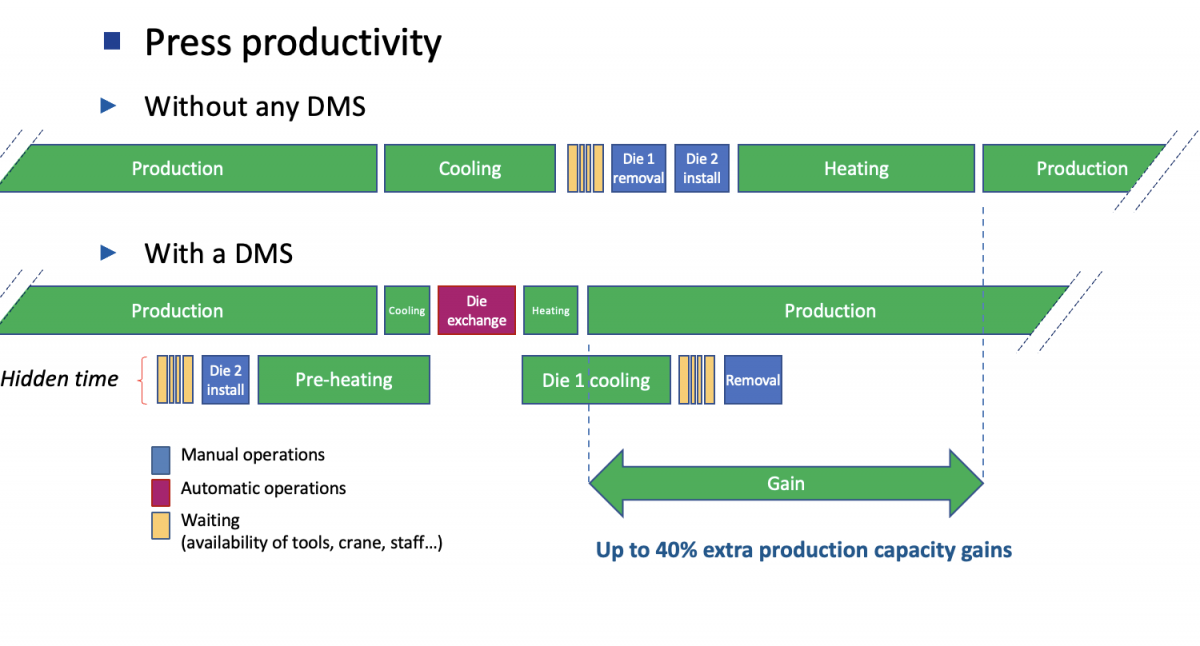

- Reliable and repeatable operation: 100% repeatable accurate die positioning

- Immediate and short operation: Up to 40% extra production capacity gains

- Improved safety: 0 human presence during die transfers to/from the press, 0 human presence close to a hot die during any handling

- Controlled cooling of the dies : No risk of abnormal wear

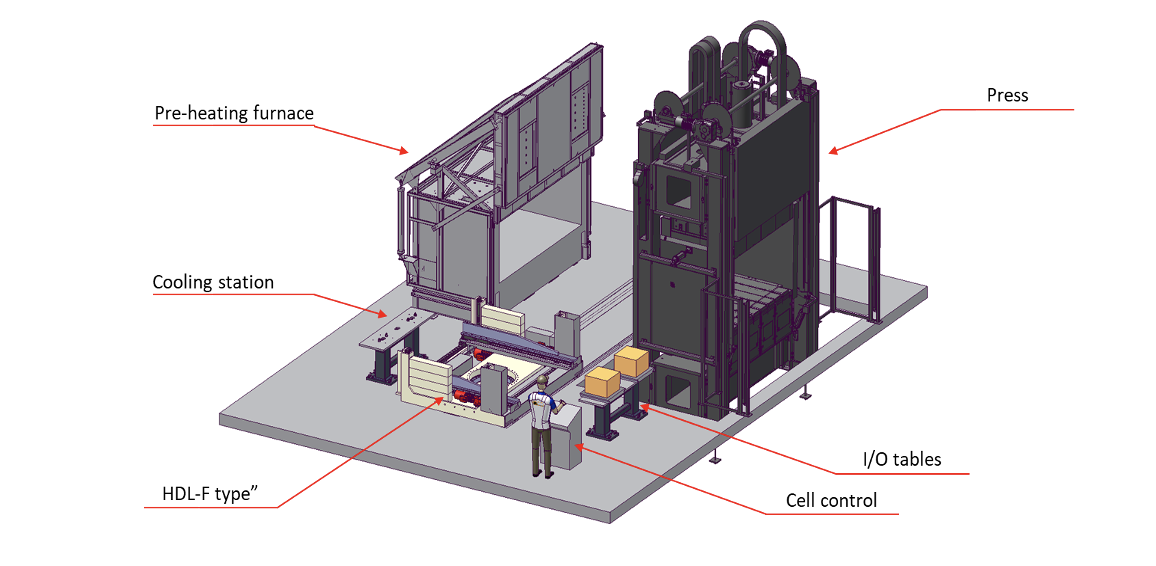

HDL-F

- During the on-going production, a next die can be introduced and pre-heated in a dedicated furnace. In the meanwhile, the previous die can go on cooling, then be extracted. All die transfers are automatically performed by the Hot Die Loader.

- The press, the HDL and the ancillary equipment are enclosed in a safe and controlled area: the HDL cell. (For production, the operator side of the press is outside the cell)

- As soon as the on-going production is completed, on request of the press operator, the die is transferred to a cooling station and the next die is transferred from the pre-heating furnace to the press to start the next production.

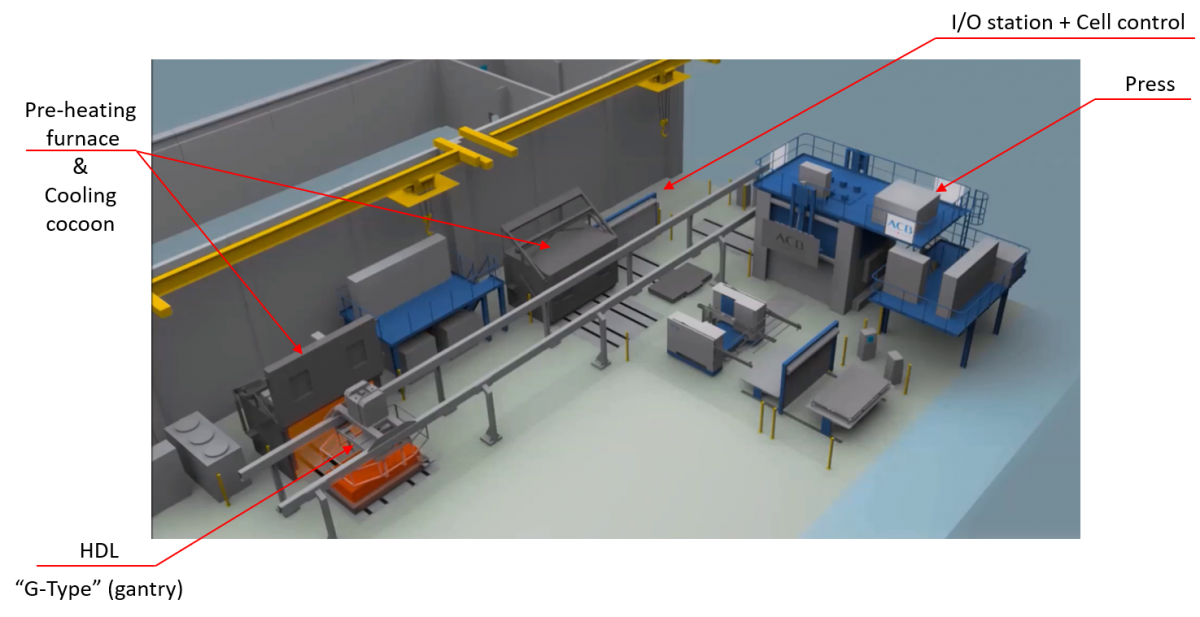

HDL-G

Typical content of the solution:

- The HDL-G,

- 1 pre-heating furnace,

- 1 cooling cocoon,

- 1 I/O station,

- The safety guarding,

- The upgrade of the press control system,

- A cell supervision.