Linear Friction Welding is a solid state welding at forging temperature. The heat is generated by the friction.

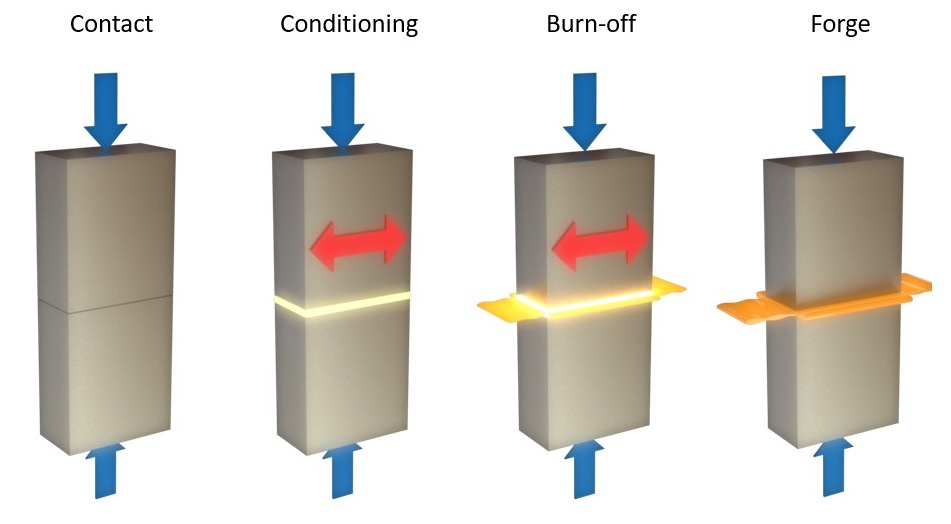

The process is generally divided in 4 phases:

- Contact: the 2 parts are put in contact

- Conditioning: pressure is applied and oscillation motion starts

- Burn-off: pressure and motion are still applied and the material is expelled

- Forge: oscillations are stopped and pressure is held during cool down

Benefits of the linear friction welding process

- Excellent mechanical properties

- High productivity

- Guaranteed process quality

Near net shape manufacturing improves buy-to-fly ratio and reduces machining costs.