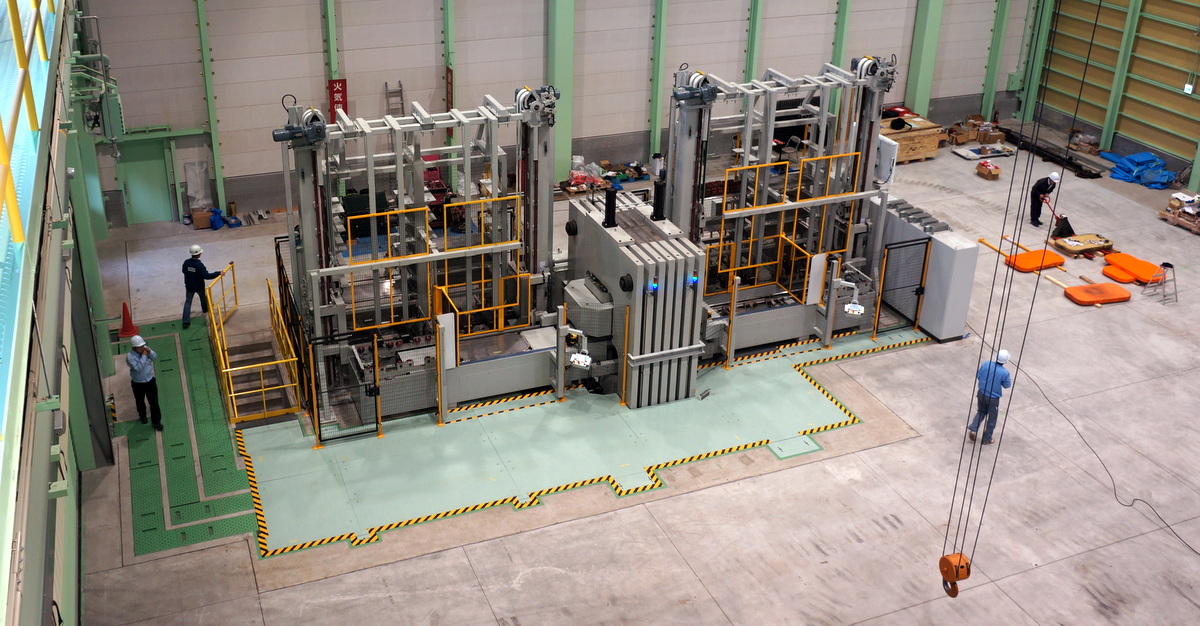

DMS system with a lift and 14 tables

During production, the press operators focus on the on-going production, they load the blanks and retrieve the parts after forming.

In hidden time, a logistics operator can prepare the next sets of dies on extra press tables, either in a dedicated logistics area, or directly on the output slot of the DMS.

When the on-going production is completed, the press operator just requests the installation of the next table.

The swap of tables is automatically performed, and the previous table is automatically transferred on the output slot.

The operators can organize their tasks and work in ideal conditions:

- The press operators only focus on the production of parts,

- The logistics operator woks with a good ergonomics and can focus on the best possible arrangement of the dies on the tables

As soon as the production is completed, the next table is automatically installed within about 30 sec ; the operator can start the production immediately after:

- Safe operation: 0 human intervention during the table changeover

- Immediate and short operation: Up to 50% extra production capacity gains

DMS made of a carousel with 12 tables